Absolute distance interferometry

“Everyday distances” are measured with millimetre per metre accuracy in seconds or minutes.

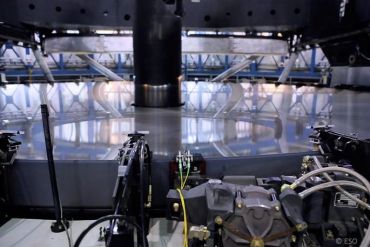

FSI systems installed on the primary mirror of the VLT (Very Large Telescope)

FSI systems installed on the primary mirror of the VLT (Very Large Telescope)Since 2005 a sequence of four research teams in Oxford’s Department of Physics helped to develop the next generation of linear particle accelerators and at the same time translate the underpinning distance measurement technology into a form beneficial to wider society.

Led by Professor Armin Reichold, these teams continuously developed extremely sophisticated laser-based distance measurement systems. They use Frequency Scanning Interferometry (FSI) in a form developed in Oxford, a revolutionary technique, capable of measuring large absolute distances to half a micron per metre - equivalent to the width of a human hair over a kilometre.

Foreseeing a wide range of potential FSI applications beyond particle detectors and accelerators, Professor Reichold initiated a collaboration with Etalon GmbH, a high-tech metrology company, since he was aware that they had the ability to reach potential commercial users of the technology.

Through a series of collaborative research projects funded by EPSRC, STFC, National Physical Laboratory, Etalon and UK industrial partner, VadaTech Plc, they applied fundamental science to commercial and scientific problems. The results were patented by Oxford University Innovation (OUI) and licensed to Etalon, who now manufacture the technology under the Absolute Multiline brand.

FSI is now used well beyond science in calibration of computer-controlled machines, power production plants and material research laboratories and on its way into car production, space simulators, aircraft manufacturing and national metrology institutes.

As Professor Reichold's research team progresses, ideas are continuously exchanged to further improve the technology for commercial and scientific applications alike. These instruments are then made available to everyone as a commercial product. The team is also currently enabling the measurement of rapidly changing distances with low latency, opening up markets such as fast control of CNC.

Funded by EPSRC, STFC, National Physical Laboratory, Etalon GmbH and VadaTech Plc