£29 million investment to support critical battery research

A £29 million investment will boost six innovative projects, four of which involve University of Oxford researchers, that are driving progress towards developing the next generation of batteries. By addressing fundamental research challenges and critical industry needs, this work is helping to unlock key battery technologies to deliver future prosperity.

Growing the battery industry is vital to positioning the UK as the best location in the world to manufacture electric vehicles. This funding will help businesses become more innovative and productive, helping to create more skilled, high-wage jobs across the UK, future-proofing our economy and supporting our ambition towards a cleaner, greener future

Nusrat Ghani, Minister of State at the Department for Business and Trade

The Faraday Battery Challenge, delivered by Innovate UK for UK Research and Innovation, is taking on the UK Government’s ambition to make the UK a science and innovation superpower for batteries, with a high-tech, high-value, high-skill battery industry. To deliver this vision, they have partnered with the Faraday Institution, the UK’s leading institute for electrochemical energy storage research, to deliver a £29 million investment to six key battery research projects aimed at delivering commercial impact.

Four of the six selected projects involve researchers from across the University of Oxford’s Mathematical, Physical, and Life Sciences Division. The investment will fund research in these areas over the next two years to 31 March 2025.

Professor Pam Thomas, CEO, Faraday Institution, commented, ‘The Faraday Institution is committed to identifying and investing in the most promising and impactful battery research initiatives. This project refocusing is an important part of that process, and allows us to direct even more effort towards those areas of research that offer the maximum potential of delivering societal, environmental, and commercial impact.’

Improved batteries for electric vehicles

Professor Mauro Pasta, from the University of Oxford’s Department of Materials, will be taking the position of Principal Investigator for the Solid-state Batteries (SOLBAT) project.

The ambition of SOLBAT is to demonstrate the feasibility of a solid-state battery that has superior performance to lithium-ion in electric vehicle (EV) applications. This could increase the range of EV batteries by safely implementing metallic lithium anodes, reduce recharging time, and address safety concerns by removing the need for flammable liquid electrolytes.

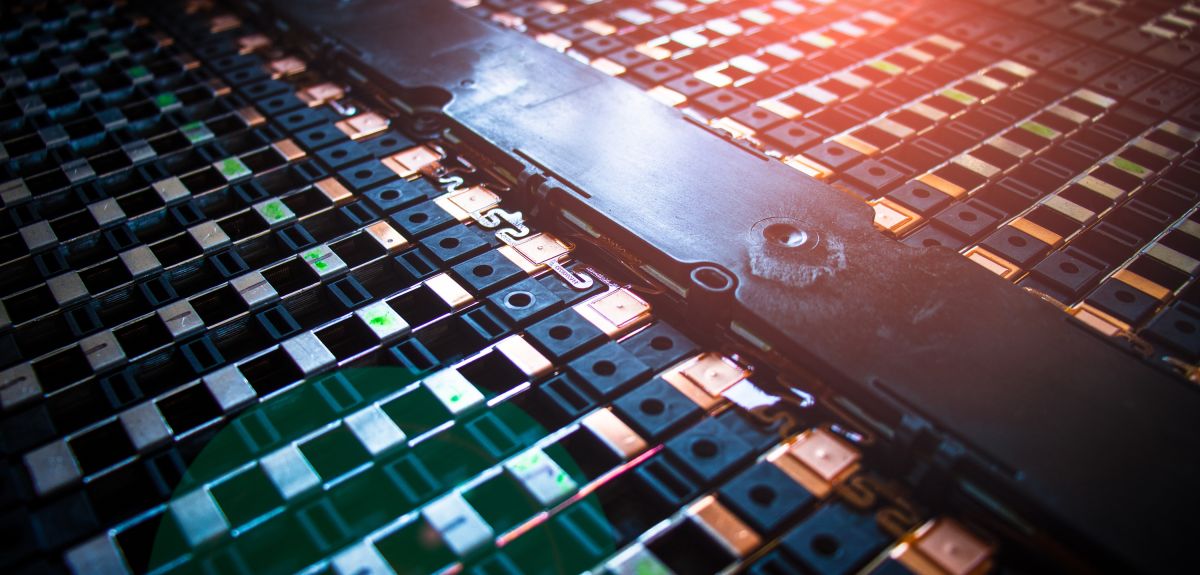

Enabling rapid charging of electric vehicle batteries will be crucial for mass adoption of this technology. Image credit: Shutterstock.

Enabling rapid charging of electric vehicle batteries will be crucial for mass adoption of this technology. Image credit: Shutterstock.

Enabling rapid charging of electric vehicle batteries will be crucial for mass adoption of this technology. Image credit: Shutterstock.

Enabling rapid charging of electric vehicle batteries will be crucial for mass adoption of this technology. Image credit: Shutterstock.SOLBAT was established to address fundamental research challenges facing the realisation of solid-state batteries, and to develop solutions that can scale to commercially competitive products. The new funding will enable the project to focus on failure mechanisms and develop solutions for anode, cathode, and electrolyte technology.

Professor Pasta said: ‘We are grateful to the Faraday Institution for the continued support of the SOLBAT project. This new investment will allow us to maintain momentum in our progress towards understanding and addressing the scientific roadblocks that are hindering the commercialisation of solid-state batteries.

The project consists of three Work Packages, led by Professor Sir Peter Bruce and Professor Patrick Grant (Department of Materials) and Professor Charlotte Williams (Department of Chemistry). Also involved as Co-investigators are Professor David Armstrong, Professor Chris Grovenor, Professor Peter Nellist and Dr Gregory Rees (Department of Materials), Professor Charles Monroe (Department of Engineering Science) and Dr Georgina Gregory (Department of Chemistry). SOLBAT also involves researchers from Newcastle University and Diamond Light Source.

Oxford researchers are also involved in the following projects to have received funding from the new investment:

Battery degradation

Led by the Universities of Cambridge and Warwick. Involving Professor Robert Weatherup, postdoctoral researchers Dr Erik Bjorkland and Dr Pravin Didwal, and DPhil student Michael Fraser from the University of Oxford’s Department of Materials.

The Battery Degradation project is examining how environmental factors and internal battery stresses (such as high temperatures and the charging process) degrade EV batteries over time. A key goal of the project is to use advanced modelling and characterisation techniques to understand the degradation of lithium-ion batteries containing high Ni-content NMC and graphite. Applying this knowledge will allow the optimisation of battery materials and cells to extend battery life (and hence EV range) and reduce battery costs. It could also help enable rapid charging of EV batteries: a crucial step towards mass adoption of the technology.

It is brilliant that researchers from a range of departments in our Mathematical, Physical and Life Sciences Division will be working on these projects in the Faraday Battery Challenge. I have no doubt that their combined expertise will enable them to innovate and optimise new generation batteries which will be crucial for sectors such as energy and transport in years to come.

Professor Chas Bountra, Pro Vice-Chancellor for Innovation at the University of Oxford

Lithium-sulfur Batteries (LiSTAR)

Led by University College London (UCL). Involving Professor Mauro Pasta , Postdoctoral student Soochan Kim and DPhil student Yvonne Chart from the Department of Materials, and Dr Georgina Gregory (Department of Chemistry).

Compared with conventional lithium-ion batteries, lithium-sulphur (Li-S) cells store more energy per unit weight, can operate in a wider temperature range, and may also offer safety and cost improvements. But widespread use of Li-S faces major hurdles that stem from sulfur’s insulating nature, migration of discharge products leading to the loss of active material, and degradation of the anode. LiSTAR is addressing these challenges by generating new knowledge, materials, and engineering solutions across four key areas: cathodes, electrolytes, modelling platforms, and device engineering. In doing so, the consortium is seeking to enable rapid improvements in Li-S technologies, with the aim of securing the UK as the global hub for the research, development, and deployment of this emergent technology.

With the new funding, Professor Mauro Pasta will lead a new work area in this project that is seeking to develop an all-solid-state Li-S battery.

Multi-scale Modelling

Led by Imperial College London. Involving Professor Charles Monroe, Professor David Howey, and Dr Nicola Courtier from the Department of Engineering Science; Professor Jon Chapman and Professor Colin Please from the Mathematical Institute; and Dr Martin Robinson from the Department of Computer Science.

Accurate simulations of batteries could enable makers to improve battery designs and performance without having to create expensive prototypes to test every new material or design. The tools that currently exist, however, typically lack the accuracy required for understanding the phenomena occurring within batteries. The Multi-scale Modelling project is addressing this by developing new digital and experimental techniques for understanding battery behaviour at a range of different physical scales (from the nanoscale to whole-pack level) and time frames (from nanosecond atomic processes through to long-term degradation). Ultimately, this will enable fast, accurate models that incorporate the most complete physics and advanced mathematical techniques, developed to be directly usable for industry.

Further information about the successful projects can be found on the Faraday Institution’s website.

British children are growing taller but not for the right reasons

British children are growing taller but not for the right reasons

Expert Comment: The war in the Gulf

Expert Comment: The war in the Gulf

International Advisory Board to strengthen global leadership in primary care

International Advisory Board to strengthen global leadership in primary care

Expert Comment: Church-to-mosque conversions grab headlines, but is funding the real crisis?

Expert Comment: Church-to-mosque conversions grab headlines, but is funding the real crisis?